Our Services

We offer a wide range of services to meet your needs

Data logging in electrical systems refers to the continuous recording and monitoring of key electrical parameters – such as voltage, current, power consumption, power factor, and harmonic distortion – over time. It provides valuable insight into how electrical systems are operating and helps identify inefficiencies, irregularities, or faults.

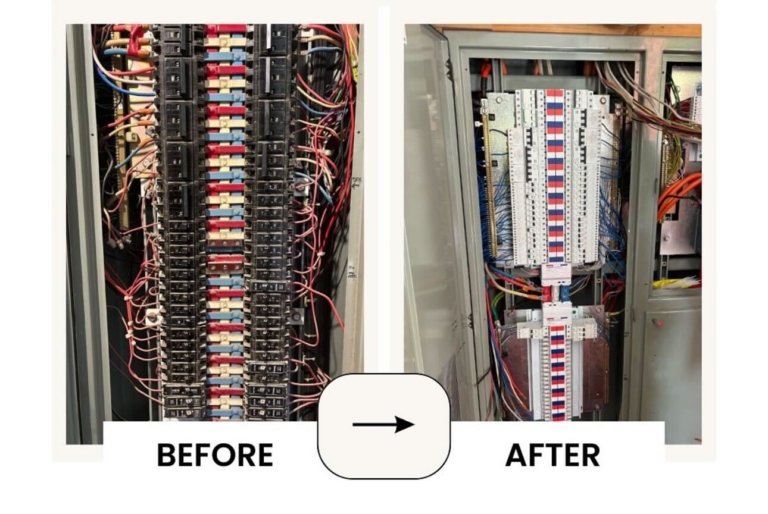

Switchboard upgrades, repairs, and maintenance are critical site works that ensure electrical systems operate safely and efficiently. These services involve replacing outdated components, enhancing capacity, addressing faults, and conducting preventive maintenance to minimize downtime. Compliance with relevant standards, including AS/NZS 3000 and AS/NZS 61439 series of standards, is integral to all site works, ensuring systems meet regulatory and operational requirements.

Metal bending and folding are essential fabrication techniques used to shape sheet metal into precise angles and forms required for custom electrical enclosures, duct covers, brackets, and other components. These processes allow flat sheets of metal to be transformed into strong, functional parts that fit perfectly within switchboards, control panels, and industrial installations.

Laser cutting is an efficient sheet metal fabrication process that uses a high-powered laser beam to cut, engrave, or mark metal components with exceptional accuracy. This advanced technology enables the creation of complex shapes, fine details, and clean edges, which are essential for manufacturing custom electrical enclosures, panels, brackets, and duct covers.

Various welding methods are used in sheet metal work, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding. MIG welding is commonly used for its speed and versatility, making it suitable for thicker materials and larger projects. TIG welding offers superior precision and a clean finish, ideal for delicate or high-quality stainless steel and aluminium work. Spot welding is often used for thin sheets, joining metal at specific points.

RMS successfully delivered two 3,200A mains and a 4,000A generator switchboard for Melbourne Quarter, overcoming complexity on time, on budget.

Learn more

For RMIT’s 1924 Capitol Theatre, RMS designed a 2000A main switchboard, 8.5m L-shaped in 11 sections, hand-carried, delivered on budget.

Learn more

After Nestlé relocated lozenge production to Campbellfield, RMS delivered a modular, type-tested power upgrade, meeting tight timelines and preventing delays.

Learn more